Contact Supplier

Mr. Liu Bin

Leave a message| Payment Type: | T/T |

|---|---|

| Incoterm: | CIF |

| Min. Order: | 1 Set/Sets |

Basic Info

Model No.: CZ22

Brand: longxuan

Type: CNC

Voltage: AC220V

Cutting Speed: 0-5000mm/min

Cutting Thickness: 51-300mm

Cutting Width: 4500mm

Cutting Nozzle Shape: Ring Type

Torch Type: Isobaric

Cutting Mode: Laser

Control Mode: CNC

Additional Info

Packaging: Wooden Box or According To Customer Requests

Transportation: Ocean

Place of Origin: Hebei, China (Mainland)

Port: Tianjin,Qingdao,Shanghai

Payment Type: T/T

Incoterm: CIF

Product Description

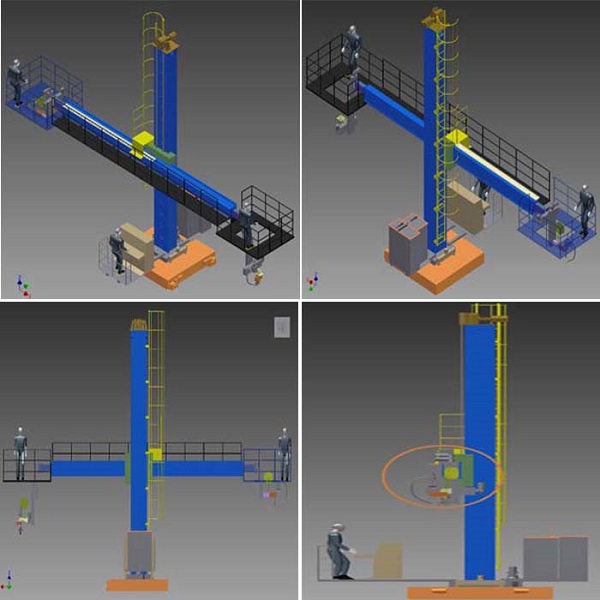

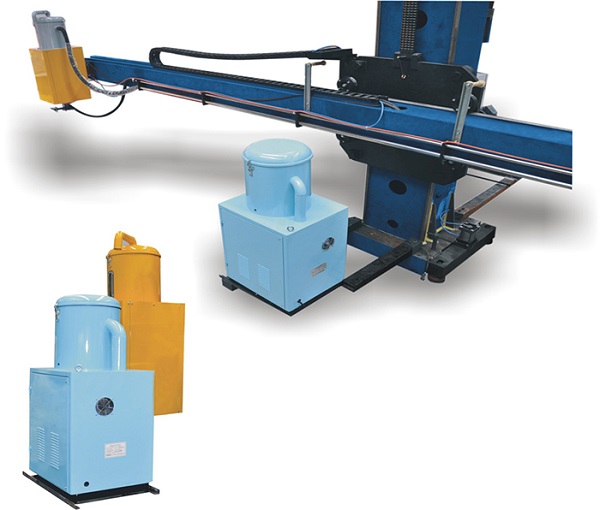

Strip Surfacing Welding Column and Boom

Samll pipe surfacing configuration: light column and boom, turning rolls, wire/strip surfacing machine or specialized wire/strip. Strip surfacing welding, replacing wire with metal strip as the welding electrode, is a kind of arc surfacing welding under the cover of melting flux or ceramic flux. It is widely used in the field of chemical industry and pressure vessel, such as wear resistance and anti-corrosion layer surfacing welding or metal roller`s repairing surfacing welding.

Scope of Application

The automatic welding column and boom is widely used in pressure vessel, refrigeration plant,

power plant,wind tower generatingequipment, aviation, metallurgy industry, engineering plant,

watercraft manufacture, roller resurfacing welding, petrochemical industry and so on.

Standard Configuration

The standard collocation includes main frame-fixed type,manual cross-saddle,spuspended

welding head, welding column and boom remote-control pendant and standard electrical control

system which can control the boom up &down,boom stretching,welding start &stop and linkage of turning rolls and positioner. Adopting trangle guide rail;Inverter control system.

Selectable Configuration

Manual or electric rotation mechanism,manual or pneumatic rotating lock mechanism,manual or electric travelling trolley,outside PLCcontroller,manual or electric cross-saddle,welding seam

tracking system,TIG wire feeding device,ALC arc length control unit,submerged arc welding head and controller.

Performance Characteristic

1. Column and boom of welding manipulators adopt high quality steel structure with good rigidity.

2. Both of column and boom of welding manipulators are rectangle structure.

3. The guide rail is manufactured by Q234/45 steel.

4. During welding the boom travelling is stable and there is no tremble that would influence the welding performance.

5. Column rotation adopts German HRS technology high precision rotation bearing which is high precision, smart rotation to assure the convenient operation.

6. Anti-drop devicehas been install on the boom.

7. The welding manipulators can integrate TIG,MIG/MAG,PAW,SAW and other welding method.

8. Trolley has two modes: travelling by manual and travelling by electric control.

Technology Parameter ( For reference only. )

Main Technology Parameter of Column

| Effective lifting range (m) | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Max. Boom height,A(using trolley & rotary table)(mm) | 3150 | 4150 | 5150 | 6150 | 7150 | 8150 | 9150 |

| Min. Boom height (using trolley & rotary table)(mm) | 1150 | 1150 | 1150 | 1150 | 1150 | 1150 | 1150 |

| Max. Boom height,B(using trolley & rotary table)((mm) | 2700 | 3700 | 4700 | 5700 | 6700 | 7700 | 8700 |

| Min. Boom height (using trolley & rotary table)(mm) | 700 | 700 | 700 | 700 | 700 | 700 | 700 |

| Max. Boom height,C(using stationary foot plate)(mm) | 2550 | 3550 | 4550 | 5550 | 6550 | 7550 | 8550 |

| Min. Boom height,(using stationary foot plate)(mm) | 550 | 550 | 550 | 550 | 550 | 550 | 550 |

| Total height,D(using trolley &rotary table)(mm) | 4600 | 5600 | 6600 | 7600 | 8600 | 9600 | 10600 |

| Total height,E(using rotary table)(mm) | 4150 | 5150 | 6150 | 7150 | 8150 | 9150 | 10150 |

| Total height,F(using stationary foot plate)(mm) | 4000 | 5000 | 6000 | 7000 | 8000 | 9000 | 10000 |

| Lifting speed(m/min) | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

Main Technonlogy Parameter of Boom

| Effective extension range (m) | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Max. Extension length,G(mm) | 2650 | 3650 | 4650 | 5650 | 6650 | 7650 | 8650 |

| Min.Extension length(mm) | 650 | 650 | 650 | 650 | 650 | 650 | 650 |

| Max. permissible loads(kg) | 350 | 350 | 350 | 350 | 350 | 350 | 350 |

| One end loads(kg) | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Distance from one end ti cross-section,N(mm) | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Cross-sectional diameter,S(mm) | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Extension speed (m/min) | 0.15-2.5 | 0.15-2.5 | 0.15-2.5 | 0.15-2.5 | 0.15-2.5 | 0.15-2.5 | 0.15-2.5 |

Pictures

Our Factory

Packing and Shipping

Company Information

Shijiazhuang Longxuan Trading Co., Ltd. is located in Shijiazhuang, the capital of Hebei Province with convenient transportation. Our company was established in Feb. 2012. Our company is professional in supplying industrial equipment, covering pipe processing machinery, automatic welding equipment, Cutting Machine, etc. Our company always adheres to "credibility and integrity, efficiency" purpose and develops rapidly, creating excellent results and our company has fostered a good image in suppliers and foreign customers. And our company has established long friendly cooperative relationships with many high-tech machinery manufacturing enterprises.

Our company will continue to provide our clients with professional quality integrated solution in automatic welding, cutting and robot welding.

For further relevant product images or details,please send your inquire Details in the below,click "Send" or contact me directly!

Product Categories : Welding Machinery > Welding Colum and Boom

Hot Products